Hand planes have been indispensable tools in woodworking for nearly two millennia, evolving through various cultures and technological advancements to become the precision instruments we know today. Their development reflects the ingenuity and adaptability of craftsmen across centuries, adapting to the demands of their times while preserving the essence of traditional woodworking.

Ancient Origins

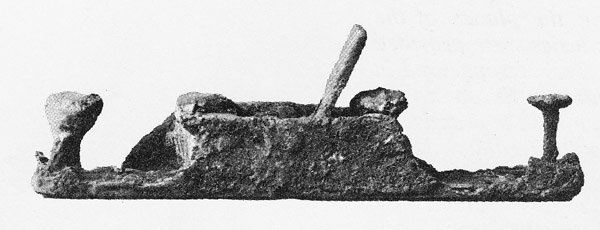

The earliest known hand planes date back to the Roman era. Archaeological excavations in Pompeii, which was buried in 79 A.D., have unearthed planes that bear a striking resemblance to modern designs. These ancient tools typically featured a wooden body reinforced with iron plating, with a blade set at an angle of approximately 50 degrees. The iron was secured using a wedge against a crossbar, and a slot was cut through the wooden core to serve as a handgrip. This design facilitated efficient smoothing and shaping of wood, laying the foundation for future innovations.

Though the Romans popularized the tool in Europe, evidence suggests that similar implements were used in ancient Egypt and China. Egyptian craftsmen, known for their mastery of woodworking, employed simple scraping tools and rudimentary planes to shape wood for furniture, chariots, and temple doors. In China, early woodworkers utilized variations of the plane as well, often incorporating different blade angles to accommodate the region’s unique timber resources.

Medieval Developments

Following the decline of the Roman Empire, detailed records of woodworking tools become scarce until the Middle Ages. Artistic depictions from this period, such as a painting by Jean Bourdichon around 1510, showcase joiners using planes with carved handles and flat-backed stocks. These illustrations indicate a continuity and gradual evolution in plane design, reflecting the enduring importance of these tools in carpentry and joinery.

By the 13th and 14th centuries, European craftsmen were producing hand planes with regional variations. English woodworkers often favored wooden-bodied planes with a distinct coffin shape, which allowed for a comfortable grip and enhanced control. Meanwhile, Dutch and French woodworkers developed their own versions, incorporating longer soles for planing large surfaces. These refinements signaled the growing specialization of planes for different woodworking tasks.

The Renaissance and Beyond

The 15th to 17th centuries marked a golden age for craftsmanship, with woodworkers demanding more specialized and efficient tools. Planes from this era often featured elaborate carvings, not merely for aesthetics but also to improve functionality and ergonomics. The introduction of the grooved wedge mechanism during the 15th century replaced the traditional crossbar and wedge system, allowing for more secure blade positioning. This period also saw regional variations in plane design, with European models commonly incorporating a forward horn to facilitate a pulling action, a feature less prevalent in English planes.

During this time, planes became more standardized in their design and function. Cabinetmakers and joiners relied on different types of planes for specific tasks—fore planes for rough shaping, smoothing planes for fine finishes, and molding planes for decorative work. The increasing availability of high-quality steel also improved blade durability, allowing for sharper and more precise cutting edges.

Industrial Revolution and Standardization

The 19th century brought significant changes to hand plane manufacturing, driven by the Industrial Revolution. The transition from wooden to metal-bodied planes addressed issues of wear and stability. Innovators like Leonard Bailey played a pivotal role during this time. In the mid-1860s, Bailey began producing a line of cast iron-bodied hand planes, introducing features that enhanced adjustability and ease of use. His designs were later acquired by the Stanley Rule & Level Company, leading to the widespread adoption of the "Stanley Bailey" planes, which set new standards for quality and functionality in woodworking tools.

Standardized manufacturing techniques allowed for mass production, making quality hand planes more accessible to professional and amateur woodworkers alike. The introduction of replaceable blades and adjustable throat openings further enhanced versatility, allowing woodworkers to fine-tune their tools to different materials and grain patterns.

Notable Manufacturers and Innovations

Several manufacturers have left an indelible mark on the history of hand planes. In Scotland, Stewart Spiers established a reputation for high-quality metal planes in the mid-19th century. His firm was known for innovative designs that combined functionality with aesthetic appeal, influencing plane-making standards in Britain. Similarly, Edward Preston & Sons, based in Birmingham, England, produced a wide range of woodworking tools from the late 19th to early 20th centuries. Their planes were celebrated for their ergonomic designs and durability, contributing significantly to the evolution of woodworking tools during that period.

In the United States, companies like Millers Falls and Sargent & Company competed with Stanley, introducing their own refinements and features. Some hand planes from this era included intricate knurling on adjustment knobs, improved chip breakers, and nickel-plated finishes for added durability.

Cultural Variations

Hand planes have also evolved differently across cultures. For instance, Japanese planes, known as "kanna," are traditionally pulled toward the user, contrasting with the Western practice of pushing the plane away. This difference reflects distinct woodworking philosophies and techniques developed independently in various regions. The Japanese approach emphasizes a harmonious interaction between the craftsman and the tool, resulting in unique plane designs tailored to their specific methods.

Similarly, Chinese planes often feature a simple wooden body with an angled blade, optimized for their woodworking traditions. African and Middle Eastern woodworking traditions also employed distinctive planes, crafted to handle the specific types of wood available in those regions.

Modern Era and Collectibility

Today, while power tools have become prevalent, hand planes remain essential for fine woodworking and are cherished by artisans for the control and finish they offer. Antique planes have become collectible items, appreciated not only for their functionality but also as artifacts of craftsmanship history. Collections, such as the Prine Collection of Woodworking Planes housed at the Heinz History Center, showcase the diversity and evolution of plane designs, offering insights into the regional characteristics and technological advancements of different eras.

Woodworkers today continue to use hand planes for specialized tasks, such as smoothing surfaces, creating precise joinery, and adding delicate finishing touches. High-end manufacturers like Lie-Nielsen Toolworks and Veritas have revitalized interest in premium hand planes by producing finely engineered tools that pay homage to historical designs while incorporating modern materials and innovations.

Conclusion

The history of hand planes is a testament to human ingenuity and the relentless pursuit of perfection in woodworking. From ancient Roman designs to modern precision tools, hand planes have continually evolved, reflecting the changing needs and artistic expressions of woodworkers. Their enduring presence in workshops around the world underscores their importance, not only as tools but as symbols of the rich heritage of craftsmanship.