I remember my first woodworking project like it was yesterday. I had this grand vision of building a rustic coffee table for my living room. I watched a few YouTube tutorials, grabbed some pine boards from the local hardware store, and thought, How hard could this be? Well, let’s just say that table ended up wobbling so much it could have doubled as a seesaw. I made nearly every beginner mistake in the book. And that’s the thing about woodworking—you learn by doing, but knowing what not to do can save you a whole lot of frustration.

If you’re just starting out, you’re bound to hit a few bumps in the road. But don’t worry, I’ve been there. Here are ten common woodworking mistakes beginners make and how to avoid them so you don’t end up with a wobbly coffee table like I did.

1. Measuring Inaccurately

There’s a reason why the phrase “measure twice, cut once” is practically the first commandment of woodworking. When I first started, I’d measure in a hurry, mark my cut, and move on, only to realize that I was off—sometimes by just a fraction of an inch, sometimes by an embarrassing amount.

The problem is that even the smallest miscalculation can throw off an entire project. Suddenly, joints don’t fit, shelves are uneven, and your finished product looks nothing like you imagined.

The best way to avoid this? Slow down. Use a quality measuring tape, and always double-check before cutting. A small tip that changed everything for me was using a marking knife instead of a pencil for precision. It creates a fine, accurate line that doesn’t smudge or mislead you like a thick pencil mark can.

2. Choosing the Wrong Wood for the Project

In the early days, I picked wood based solely on appearance. If it looked nice at the lumber yard, I assumed it would work for my project. Big mistake. Some woods are easier to work with than others, and beginners should start with those.

For instance, softwoods like pine are great for starting out because they’re easy to cut and shape. Hardwoods, on the other hand, like oak or maple, require sharper tools and a bit more finesse. I once tried making a simple shelf with oak, not realizing how difficult it was to work with. My saw struggled, my drill bit burned through it instead of cutting, and I nearly threw in the towel.

Lesson learned: choose your wood wisely. If you’re unsure, ask someone at the lumberyard for advice, or stick with beginner-friendly options like pine or poplar.

3. Ignoring Wood Grain Direction

Wood grain matters—a lot. I didn't realize this when I started, which led to a lot of rough, splintered edges and even some cracked boards.

The first time I planed against the grain, I thought I had ruined my entire project. Instead of a smooth surface, I ended up with a fuzzy, torn mess. The grain dictates how the wood will react when you cut, plane, or sand it. Working against it often results in rough surfaces or unsightly tear-out.

To avoid this, always check the grain before making cuts. If you're sanding or planing, go with the grain, not against it. If you’re unsure, run your hand along the board—one direction will feel smooth, and the other will feel rough. Go with the smooth direction.

4. Not Sharpening: Using Dull Tools

There’s nothing more frustrating than struggling through a cut, wondering why it feels like you're sawing through a rock, only to realize your blade is dull. I used to think I could get away with using the same saw blade or chisel for way too long, and all it did was lead to more effort, frustration, and poor-quality cuts.

A sharp blade makes all the difference. Not only does it make cutting easier, but it’s also safer because you don’t have to use excessive force, which can lead to slips and injuries. If you’re noticing burn marks on your wood or jagged edges, it’s time to sharpen or replace your blade.

5. Rushing the Process

When I first started, I wanted results yesterday. I’d rush through a project, skipping steps I thought were unnecessary. Why bother waiting for glue to dry fully when it looks dry? Why take the time to sand properly when I could just slap some finish on?

Spoiler alert: It never ended well.

One project in particular, a small side table, ended up with wobbly legs because I didn’t wait long enough for the glue to fully set before attaching the screws. I also rushed through the sanding, which left a rough finish that became even more noticeable after staining.

Woodworking isn’t about speed—it’s about precision. Take your time, follow the steps, and resist the temptation to cut corners. It’s worth it in the end.

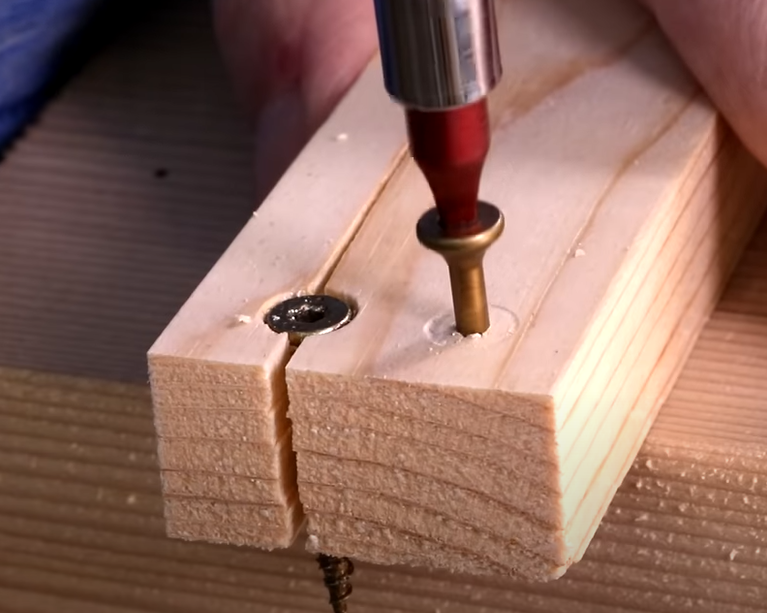

6. Skipping Pre-Drilled Holes

I once tried to drive a screw directly into a piece of hardwood without pre-drilling, thinking, Eh, I’ll save time. Instead, the wood split right down the middle. That’s when I learned about the importance of pre-drilled holes.

Drilling pilot holes before inserting screws prevents the wood from splitting and makes for a much cleaner, easier build. If you’re working with hardwood, it’s even more critical.

7. Rushing Through Sanding

Sanding is tedious. I get it. But skipping it or doing it half-heartedly will ruin an otherwise great project. I used to stop at 120-grit sandpaper because I figured it was “good enough.” But when I applied stain, the wood absorbed it unevenly, highlighting every flaw.

The key is to sand gradually, starting with a lower grit (80-100) and working your way up to 220 for a smooth, professional-looking finish. And always, always sand with the grain.

8. Using Too Much Glue

Early on, I thought the more glue, the better. I’d slather it on, assuming it would create a stronger bond. Instead, it created a messy project with glue oozing out of every joint.

Glue should be applied sparingly—just enough to coat the joint. If excess glue squeezes out, wipe it away immediately with a damp cloth before it dries.

9. Neglecting Safety

I’ll admit, I’ve skipped safety goggles before because they felt annoying. That was until a tiny wood chip flew straight into my eye while cutting a board. Lesson learned.

Always wear safety glasses, ear protection (power tools are louder than you think), and a dust mask if you're working with materials that create fine particles. It might seem like overkill, but it’s not.

10. Not Having a Clear Plan

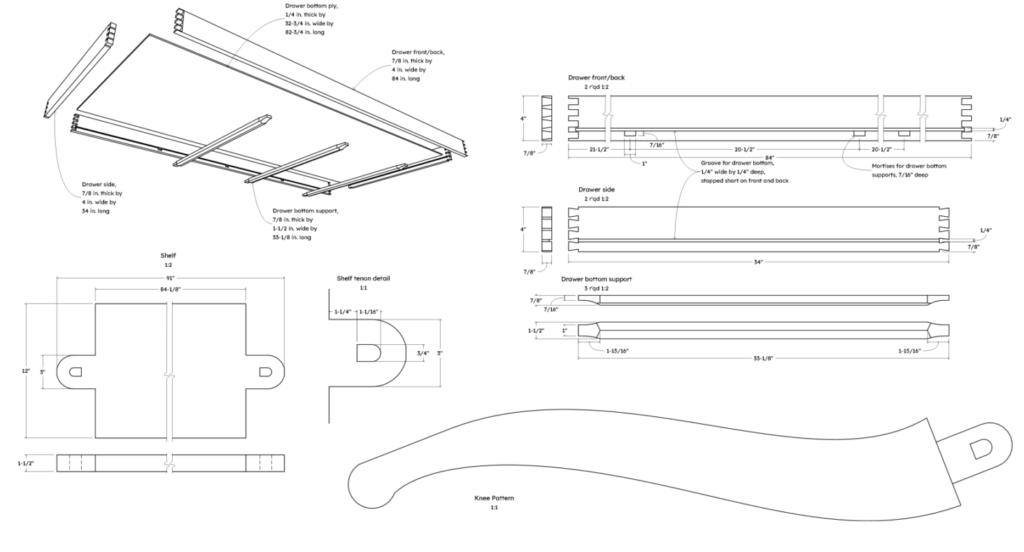

When I first started woodworking, I’d dive into a project without any real plan, thinking I’d figure it out as I went. That approach led to a lot of wasted wood and a lot of frustration.

Now, I take the time to sketch out my projects, create a cut list, and plan each step. It makes the process smoother and eliminates guesswork. If you’re a beginner, start with detailed plans—there are tons of free ones online.