MDF

While MDF is not technically a plywood, however, it is a sheet good that is commonly used in cabinet and furniture construction due to its inherent stability and cost.

MDF (Medium Density Fiberboard) sheet goods are engineered wood products made by breaking down hardwood or softwood residuals into wood fibers, often in a defibrator, combining them with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is denser than plywood and has a smooth, uniform surface, which makes it ideal for painting and machining. It is used extensively in furniture, cabinetry, molding, and interior projects due to its versatility, ease of use, and affordability. MDF sheets come in various thicknesses and sizes, offering a cost-effective alternative to solid wood while providing a similar finish. However, they are more susceptible to moisture damage and may release formaldehyde, necessitating careful handling and use in well-ventilated areas.

Cabinet Grade Plywood: Where To Buy?

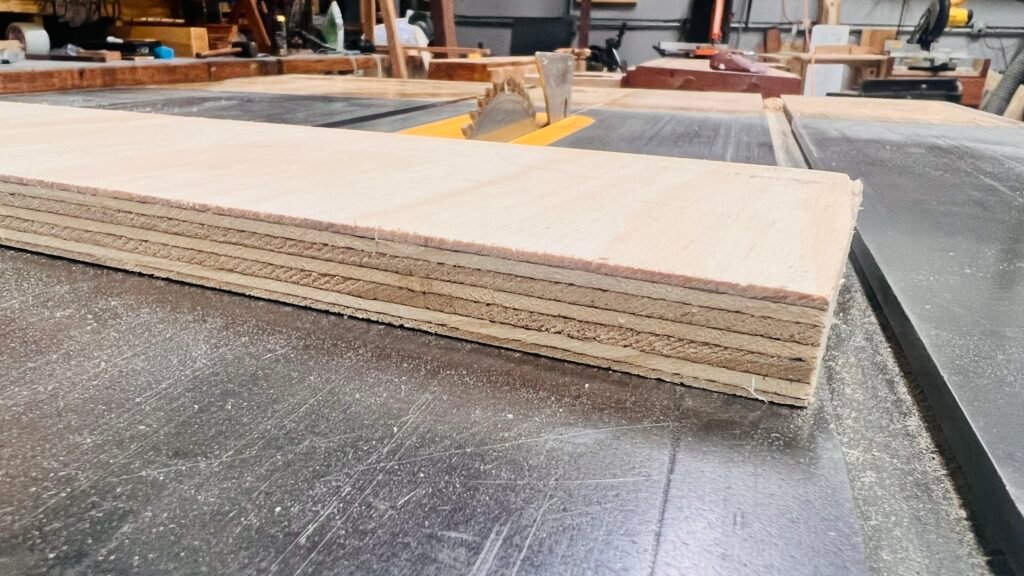

The plywood found at your big box stores will be of varying quality but there is one major difference between plywood you purchase there and true cabinet-grade plywood and that is the number and thickness of the laminated veneers in a 3/4in sheet. While Home Depot carries prefinished plywood in maple, birch and possibly oak. The plywood found at stores like Home Depot will generally only have 5-7 ply's and a thin finish veneer. True cabinet-grade plywood will have 12-15 plys which makes it much more stable and less prone to any bowing or warping, the finish veneer is also typically thicker. I like Baltic Birch as it uses a thicker veneer for the face and back and you are much less likely to sand through it or scratch it all the way through.

Understanding Letter and Number Grades

Plywood grading can be a bit confusing if you have never seen it before but let's break it down so you can understand what it means and why it's important.

Grades:

Plywood is graded from best to worst as A, B, C, and D for the front face, while the back face is graded 1, 2, 3, and 4 in descending quality. These grading standards are established by the Hardwood Plywood & Veneer Association.

Plywood grades A1, A2, B1, and B2 are high-quality, two-sided options suitable for projects where both faces will be visible. While the back side (number grade) may have slight blemishes, it remains relatively clean.

Grades A3, B3, and C3 are ideal for applications where only one side is exposed. The back may have minor imperfections, such as discoloration, spliced veneer, or stains, but remains structurally sound. This type of plywood is often used for dresser sides, drawer interiors, and shelving—areas where the back is rarely seen.

A and B Grades

Grade A

- Smooth Surface:

- Appearance: The face veneer of Grade A plywood is smooth, defect-free, and often sanded, making it ideal for finishing with paint, stain, or clear coats.

- Minimal Defects: It has minimal knots, splits, or voids. Any small defects are typically filled and sanded to ensure a smooth surface.

- High-Quality Veneer:

- Uniform Grain: The veneer on Grade A plywood is typically of high quality with a uniform grain pattern, making it aesthetically pleasing.

- Consistent Thickness: The veneers are of consistent thickness, which contributes to the panel's overall strength and stability.

- Durability:

- Structural Integrity: Grade A plywood is constructed with high-quality adhesive, which contributes to its durability and resistance to delamination.

- Multiple Plies: It often has more plies than lower grades, which enhances its strength and resistance to warping and bending.

Benefits

- Superior Finish: The smooth and defect-free surface is perfect for applications where appearance matters, as it can be easily painted or stained to a high standard.

- Ease of Use: The high-quality veneer and consistent thickness make it easy to work with, whether cutting, sanding, or machining.

- Strength and Stability: The multiple layers and high-quality construction provide excellent strength and stability, suitable for structural applications.

Common Uses

- Cabinetry and Furniture: Grade A plywood is often used for making high-end cabinetry, furniture, and shelving where a fine finish is required.

- Interior Panels: It is ideal for interior wall panels and ceiling applications where aesthetics are important.

- Doors: Used in the construction of interior and exterior doors due to its smooth surface and durability.

- DIY Projects: Popular among DIY enthusiasts for making detailed and decorative projects that require a high-quality finish.

Grade B

Grade B plywood is a high-quality plywood with a smooth, sanded surface and minor defects. It is one step below Grade A in quality but still offers good durability and workability. Grade B plywood is often used in applications where appearance is important but minor imperfections are acceptable. It is commonly paired with an A-grade face in A/B plywood (smooth front, slightly imperfect back) or used in B/C plywood for projects where one side is hidden.

- Smooth surface: Sanded and suitable for painting or staining, though not as flawless as Grade A.

- Minor defects: Small knots (up to 1 inch in diameter), slight discoloration, or small patches may be present.

- Durability: Strong and stable, making it suitable for construction, furniture, and cabinetry.

- Veneer repairs: Some imperfections may be repaired with wood filler or patches.

Difference in Grade Notation:

Some plywood manufactures might notate plywood grades differently than the Letter(face), number(back) notation

It is common to see letter grades for both the front and the back.

- B/BB: Features a single-piece face and back veneer. The face is clear, defect-free, and has a light, uniform color. The back allows 3-6 oval, egg-sized, color-matched patches. The inner core consists of solid birch single-piece veneers.

- BB/BB: Both the face and back are single-piece veneers, each allowing 3-6 small, color-matched patches and occasional light mineral streaks. Tight pin knots may also be present. The inner core is made of solid single-piece veneers.

- BB/CP: Features a single-piece face and back. The back veneer ("CP" grade) is downgraded from "BB" grade, allowing unlimited patches and sound knots while prohibiting open defects. The inner core consists of solid birch single-piece veneers.

- CP/CP: A single-piece face and back veneer, both allowing unlimited sound knots, repaired splits, and patches. The panel is structurally sound on both sides and is intended for laminating.

- C/C: Allows patches, open knots, and small veneer splits. Veneer laps and small core voids are permitted. This panel is not sanded and is primarily used for structural purposes.

- Shop Grades: These panels are available in the full 60” x 60” format across all listed grades. They may have 1-3 splits along one edge of the face veneer, with a maximum length of 10” and a width of ¼”. Shop-grade panels are sold at a significant discount compared to standard grades.

Check With Your Supplier

It is also a good idea to check with your supplier and examine the plywood yourself. Due to the nature of wood sometimes the difference in product can be drastic and things such as supply chain issues and sourcing region, play a huge role in the type of product you would see at your local stores.

During a period of time, Baltic Birch plywood was almost impossible to get and so maple veneer plywood was much more common, later, the same maple that was available was no longer available and AA or A1 maple had a core that was comprised of 5 ply's instead of the 13 it had before.

It's a good idea to get to know your local hardwood and plywood supplier and see how the quality compares to the grading they give it.

Sometimes my local store has shop grade maple that looks very good and is almost free of defects on one side, it is certainly good enough quality to use as paint grade.